2019W2

HYBRID COMPONENTIALITY 2.2: D2RP&O

CONTENT & APPROACH

This workshop introduces students to computational design strategies for Design-to-Robotic-Production and -Operation (D2RP&O) in order to achieve material and process efficiency as well as physical and/or sensorial reconfiguration. Students are asked to identify aspects related to robotic production and operation that are relevant for the Off-Earth Habitat project and map those onto the proposed schematic design. The exercise focuses on hybrid componentiality, which implies that components of various materials and properties are interconnected to establish together a multi-performative whole.

Three D2RP&O studies are proposed:

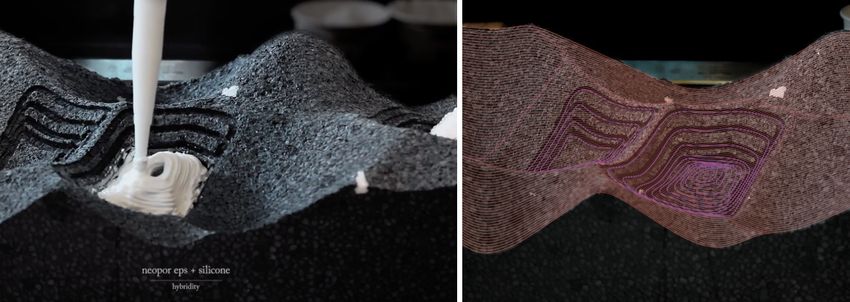

1. Subtractive D2RP: The development of a structurally optimized wall/ceiling/floor component milled from EPS ,

2. Additive D2RP: The development of a 3D printed acoustically optimized layer on top of the milled wall/ceiling/floor component,

3. D2RO: The of development of interactive/responsive lighting/ventilation/heating system fitted with sensor-actuators and integrated in/onto the wall/ceiling/floor component,

4. D2RO: The development of a reconfigurable inflatable space-furniture component.

To be considered are current developments in computational design, robotics, additive manufacturing, cyber-physical systems, machine learning, adaptive/interactive environments. Main questions to be answered are: If static structures harbor dynamic components that can be reconfigured, what are the utopian/dystopian scenarios that are considered, which are the static and the dynamic components, what is the required degree of customisation and how it is to be achieved. Potential customization is explored though functional, environmental, acoustical and structural simulations.

DELIVERABLES

a. 1 to max. 2 minutes video of D2RP process,

b. Report (1500 words) consisting of textual and photo/graphical documentation of physical prototypes and design to fabrication process developed during the semester,

c. Clean Rhino and Grasshopper files and refined version D2RP procedures,

d. 3D printed model, 1:1 prototypes, and tests.

COORDINATORS & TUTORS

Henriette Bier, Arwin Hidding, and Vera Laszlo

STUDENTS

Groups 1, 2, 3 and 4.