Difference between revisions of "Shared:2023W4G2HRI"

(→HRI Video) |

(→HRI Video) |

||

| Line 48: | Line 48: | ||

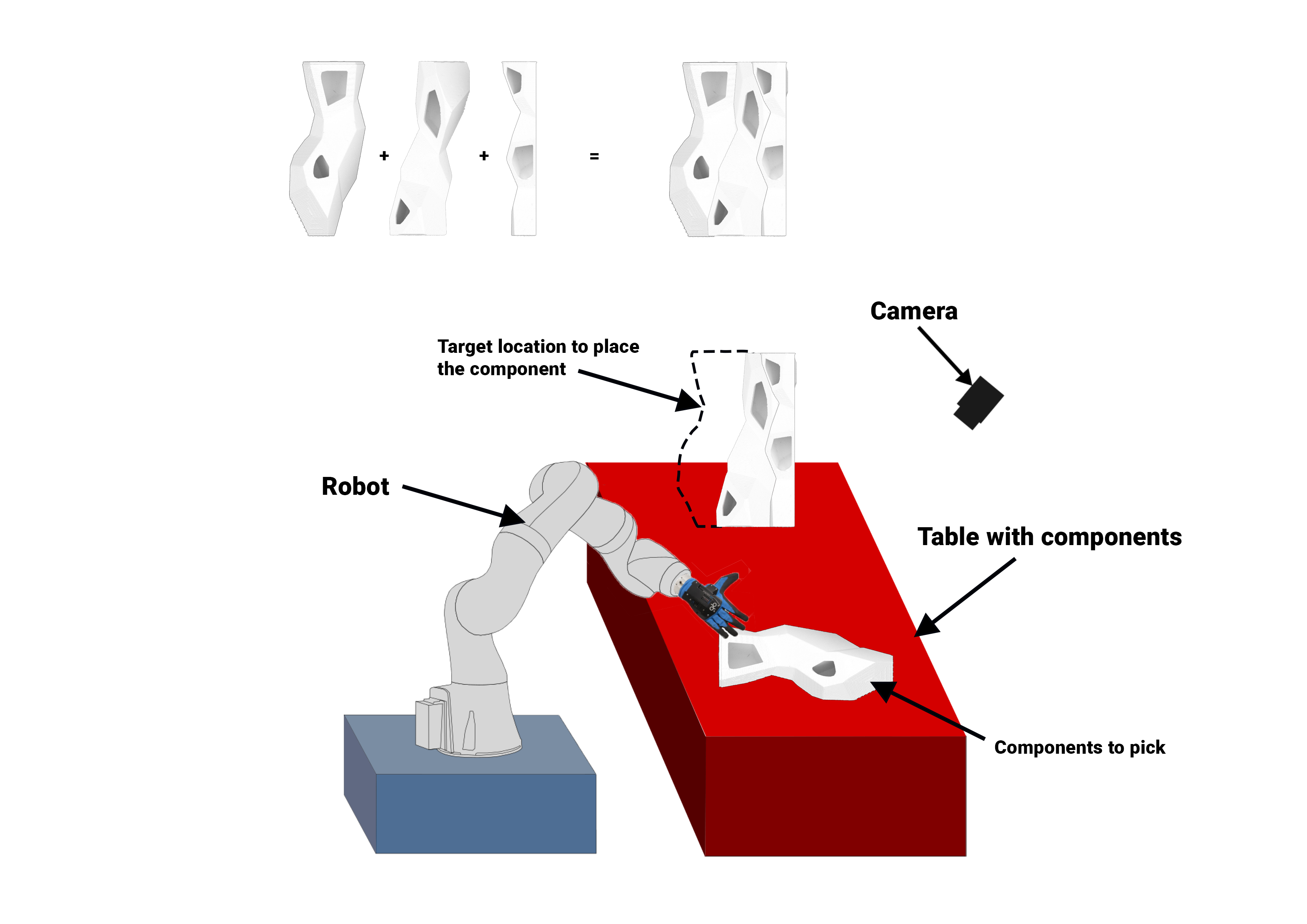

In Figure 1, a camera is used to locate the position of the table with its marked elements, which are recognized by software. The elements that are placed on the table are identified, and a Python program is utilized to determine the coordinates of the largest edge of a specific element. The robot arm is then directed to move towards this location and pick up the element from that edge with a particular angle. This process highlights the robot's ability to identify and manipulate objects with accuracy, while reducing the physical demands on human workers. | In Figure 1, a camera is used to locate the position of the table with its marked elements, which are recognized by software. The elements that are placed on the table are identified, and a Python program is utilized to determine the coordinates of the largest edge of a specific element. The robot arm is then directed to move towards this location and pick up the element from that edge with a particular angle. This process highlights the robot's ability to identify and manipulate objects with accuracy, while reducing the physical demands on human workers. | ||

| + | |||

| + | [[File:IAP2023_HRI_group2.png]] | ||

| + | Figure 1: Overview of the experimental setup with robot and assembly components. Target for placing the component is shown with a dashed line. | ||

Once the robot picks up the element, it can be carried through a collaborative effort between the human worker and the robot. The robot can be guided to a specific location, which in this case is indicated by the dashed lines in the picture. The element can be attached to other components or held in place for future fixation. Although the process of carrying the element to a specific coordinate can be done through programming, it is considered a more active collaborative action due to the complexities and the need for accurate fixation. | Once the robot picks up the element, it can be carried through a collaborative effort between the human worker and the robot. The robot can be guided to a specific location, which in this case is indicated by the dashed lines in the picture. The element can be attached to other components or held in place for future fixation. Although the process of carrying the element to a specific coordinate can be done through programming, it is considered a more active collaborative action due to the complexities and the need for accurate fixation. | ||

Revision as of 17:14, 20 April 2023

Settling between the cracks of Mars

Group 2: Mohammad Behboodi - Sumeet Joshi - Dost Sahingoz - Majd Shahoud

HRI Video

Video

Introduction

The objective of this practical assignment is to gain an understanding of how robots can assist human workers in carrying out assembly tasks. Specifically, the task involves the selection and placement of a component into a designated node with the assistance of a robot (as demonstrated in figure 1). In this process, the robot’s function is to identify building components using computer vision and to provide support to the human operator by shouldering the majority of the workload during assembly. The human operator, on the other hand, is responsible for utilizing their advanced cognitive abilities to manage the more intricate aspects of the task, including overseeing the handling and manipulation of pieces, orienting the pieces that the robot is manipulating, and ensuring that the task is completed safely and effectively. This interactive exercise is intended to serve as a practical demonstration, enabling participants to gain hands-on experience with the application of robotic technology in assembly tasks.

Practicum

In Figure 1, a camera is used to locate the position of the table with its marked elements, which are recognized by software. The elements that are placed on the table are identified, and a Python program is utilized to determine the coordinates of the largest edge of a specific element. The robot arm is then directed to move towards this location and pick up the element from that edge with a particular angle. This process highlights the robot's ability to identify and manipulate objects with accuracy, while reducing the physical demands on human workers.

Figure 1: Overview of the experimental setup with robot and assembly components. Target for placing the component is shown with a dashed line.

Figure 1: Overview of the experimental setup with robot and assembly components. Target for placing the component is shown with a dashed line.

Once the robot picks up the element, it can be carried through a collaborative effort between the human worker and the robot. The robot can be guided to a specific location, which in this case is indicated by the dashed lines in the picture. The element can be attached to other components or held in place for future fixation. Although the process of carrying the element to a specific coordinate can be done through programming, it is considered a more active collaborative action due to the complexities and the need for accurate fixation.