Difference between revisions of "Shared:2023W4G1HRI"

| Line 48: | Line 48: | ||

[[File:HRI DIAGRAM FINAL.png|850px]] | [[File:HRI DIAGRAM FINAL.png|850px]] | ||

<br> | <br> | ||

| + | <br> | ||

| + | |||

The human guides the robotic arm to a specific point which will have a designated value assigned to it. These presets are important in guiding where the robot needs to be during specific points in the operation. It also helps the robot recognise where certain physical obstacles are in the lab, such as the table. | The human guides the robotic arm to a specific point which will have a designated value assigned to it. These presets are important in guiding where the robot needs to be during specific points in the operation. It also helps the robot recognise where certain physical obstacles are in the lab, such as the table. | ||

<br> | <br> | ||

Latest revision as of 15:44, 30 April 2023

Prototype water research station for the human endeavour of discovering water on Mars.

Group 1 Arno Decorte - Tom Punte - Augusta Fiseryte

HRI

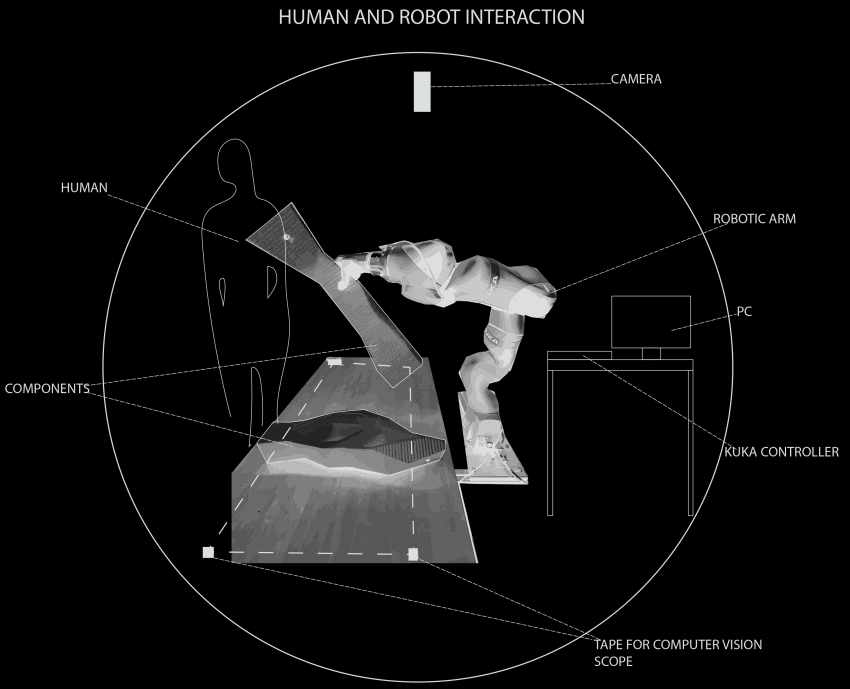

The final stage of the prototyping process involved simulating human robot interaction and how we can assemble these fragments using the aid of a robotic arm.

Calibration

Before we detect the fragments, the KUKA robot needs to be aware of where the physical obstacles are in the area as well as where it needs to start before the operation begins. This process is known as calibration, and it involves the manual input of a human.

The human guides the robotic arm to a specific point which will have a designated value assigned to it. These presets are important in guiding where the robot needs to be during specific points in the operation. It also helps the robot recognise where certain physical obstacles are in the lab, such as the table.

Fragment Detection

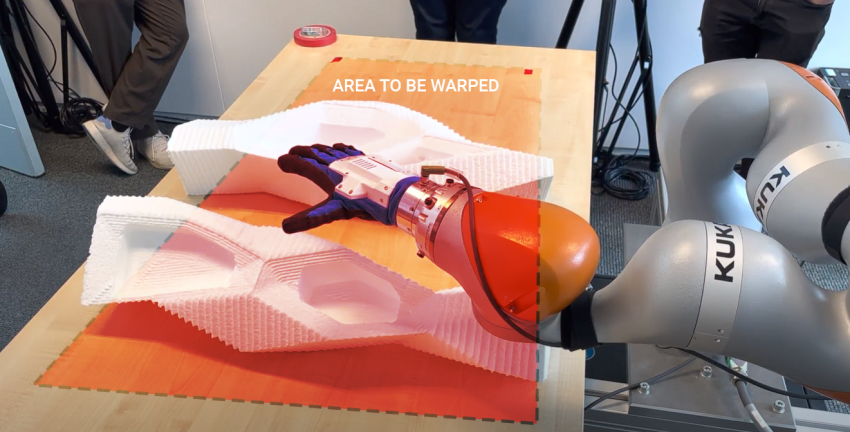

Before the actual assembly process can begin, the KUKA arm needs to be calibrated to ensure that it is operating within the required accuracy and precision.

In order to do this, we use computer vision to highlight the location of the fragments on the table. We then warp the image so that the KUKA robot is able to locate precisely where the fragments are on the workspace.

Assembly

The final step would be to use the KUKA arm to assemble the foamboard fragments by connecting them together using an adhesive or other joining method.