Shared:2019Final

Off-Earth Manufacturing and Construction (of Habitats)

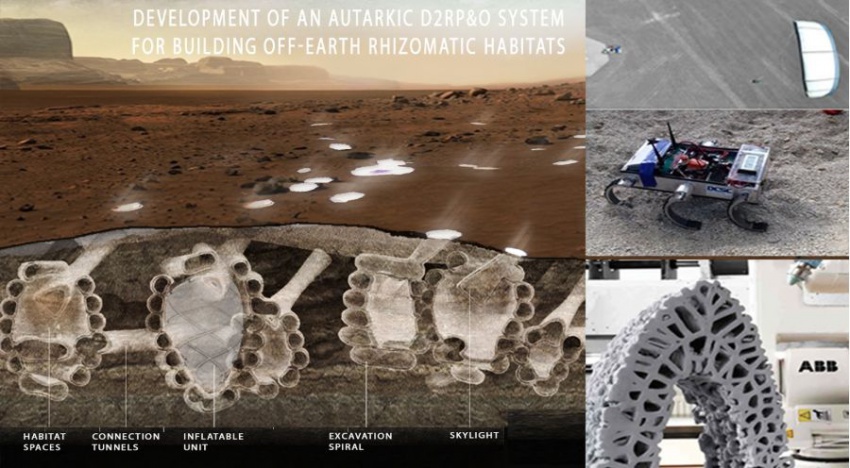

Fig. 1: Underground rhizomatic structure with skylights

Fig. 1: Underground rhizomatic structure with skylights

PHASE 1

Title

Rhizome: Development of an Autarkic Design-to-Robotic-Production and -Operation System for Building Off-Earth Rhizomatic Habitats

Keywords

Autarkic system, data-driven design, robotic production, habitat, sun and wind energy

Source

https://docs.google.com/document/d/1mhVsgoEXEYoK15unSvxkDXwVpIuzrSBbU75VOPGs6Lg/edit

Team

The University of Technology (Dutch: Technische Universiteit) Delft is also known as TU Delft, is the largest and oldest Dutch public technological university, located in Delft, Netherlands. As of 2019, it is ranked in the top 20 best universities for engineering and technology worldwide and is the highest-ranked university in the Netherlands. The team consists of researchers and students with various backgrounds and expertise: Dr. Henriette Bier (architecture: RB), Dr. Roland Schmehl (aerospace: wind energy), Dr. Angelo Cervone (aerospace: space systems engineering), MSc. Arwin Hidding (architecture: RB), MSc. Arise Wan (architecture: RB), MSc-cand. Edwin Vermeer (architecture: RB), BSc-cand. Maneesh Verma (aerospace: swarm robots), MSc-cand. Krishna Jani (architecture: RB), MSc-cand. Emma Chris Avramiea (architecture: RB), and MSc-cand. Siddharth Popatlal Jain (architecture: RB). 3 groups from two TU Delft faculties participate in this proposal:

Architecture and the Built Environment: Robotic Building (RB)

The Architecture Faculty at TU Delft is ranked third in the world after MIT and Bartlett. The Robotic Building group has been established in 2014 with the first robotic lab at the Architecture Faculty (http://www.roboticbuilding.eu/about/). Its research and education focus on (a) physically built robotically augmented environments and (b) robotically supported building processes. Reconfigurable, robotic environments incorporating sensor-actuator mechanisms that enable buildings to interact with their users and surroundings in real-time may require the design to production, assembly, and operation chains that may be (in part or as a whole) implemented by robotic means. In several funded projects the group has developed expertise in 3D printing with ceramic clay, thermo-plastic elastomers, and silicon.

Aerospace: Space Systems Engineering

Through the Space Systems Engineering chair of the Aerospace Engineering Faculty, TU Delft plays a leading role in the European research on space systems engineering, distributed space systems and nanosatellite design as well as radio hardware, analogue and digital circuit design, micro-systems technology. Research activities at the Space Systems Engineering chair focus on enabling technologies within space engineering. The chair research strategy is to realize complex space systems in an end-to-end engineering approach. In the last 10 years, the department has successfully developed, launched and operated in space the Delfi-C3 and Delfi-Next satellites, and is consequently recognized worldwide as a flagship in nano-satellite development. An important part of the Space Systems Engineering research activities is dedicated to the Delfi program, within which end-to-end engineering of miniaturized satellite platform is conducted in close synergy with the educational activities of the group. Recent projects in which the chair has been involved include: Stardust-R, an extensive consortium of 22 European and international partners on the exploration and exploitation of asteroids to make the use of space sustainable; LUMIO, a Cubesat mission for micrometeoroid impact detection on the Lunar far side; FleRaSS, a project related to the design of a flexible radio science system for new generation spacecraft; QB50, an international network of 50 CubeSats for lower thermosphere measurements and re-entry research.

Aerospace: Airborne wind energy

The Airborne Wind Energy Research Group is part of the Section of Wind Energy and a pioneer in the exploration of innovative wind energy solutions using tethered flying devices. From 2010 until 2015, the group has operated a unique 20 kW kite power system at their test center on the former Naval airbase Valkenburg, demonstrating automatic operation first in 2012. Since 2016 the technology is scaled up to 100 kW and commercially developed by spin-off company Kitepower BV. The research group has coordinated the EU F7 project NUMIWING, the EU H2020 doctoral training network AWESCO and the EU H2020 “Fast Track to Innovation” project REACH.

Collaborators / Partners

WUR (https://wur.nl/), ESA (https://www.esa.int), DRI (https://tudelftroboticsinstitute.nl), SAM|XL (https://samxl.com), 3D Robot Printing (https://www.3d-robotprinting.com), DGF (http://dutchgrowthfactory.com), Kitepower BV (http://www.kitepower.nl).

Study

1. Development of planetary/stellar rhizomatic habitat with integrated environmental control and life-support system

2. Advancement of autarkic data-driven Design-to-Robotic-Production and -Operation (D2RP&O) system using in-situ resources and solar/kite power

3. Development of excavation and 3D printing approach using rover swarm and D2RP&O system

4. Integration/Development of sun and kite power systems

Abstract

In order for off-Earth top surface structures built from regolith to protect astronauts from radiation, they need to be several meters thick. TUD proposes to excavate into the ground to create subsurface habitats. By excavating not only natural protection from radiation can be achieved but also thermal insulation because the temperature is more stable underground. At the same time through excavation valuable resources can be mined for in situ resource utilization (ISRU). The idea is that a swarm of autonomous mobile robots developed at ESA and/or TUD (https://tudelftroboticsinstitute.nl/robots/zebro) excavate the ground in a sloped downwards spiral movement. The excavated regolith will be mixed with liquid sulphur to create concrete, which is then 3D printed to create a structure in the excavated tunnels. As soon as the tunnels are printed, the material in-between the tunnels can be removed in order to create a larger cavity that can be used for inhabitation. While excavation is implemented in a downwards spiral movement, the printing follows an upwards spiral and it relies on Design-to-Robotic-Production and -Operation (D2RP&O) technology developed at TUD (http://www.roboticbuilding.eu/project/scalable-porosity/). The rhizomatic 3D printed structure is a structurally optimized porous shell structure with increased insulation properties. In order to regulate the indoor pressurized environment an inflatable structure is placed in the 3D printed cavity. This inflatable structure is made of materials, which can also be at some point reproduced on Mars through ISRU. Depending on the location the habitat and the production system are powered by the automated kite-power system (on Mars) and/or solar panels developed at ESA and TUD (http://www.kitepower.eu/home.html, etc.). The ultimate goal is to develop an autarkic D2RP&O system for building off-earth subsurface autarkic habitats from locally obtained materials.

Introduction

Building off-Earth habitats requires the acknowledgment of three interconnected aspects: First, a different design methodology is needed as opposed to many Earth-based design methodologies; Second, the understanding of different terrestrial locations, the climate, the available materials, and local hazards all play a major role in the design to robotic production and operation process. And third, the understanding of the limits in terms of mass and volume for interplanetary space travel. Currently, the Moon and Mars are within reach for interplanetary habitation based on the current and expected level of technology readiness level likely to be reached in the near future. According to previous research, regolith, crushed rock, and dust can potentially be used as a construction material. Regolith constructions can potentially protect astronauts from large amounts of radiation. However, galactic cosmic rays would require a regolith layer of several meters thick in order to protect the astronauts sufficiently. Furthermore, regolith in itself is incapable to deal with thermal stresses that occur from large temperature swings during the day-night cycle on both the Moon and Mars. And the absence of an atmosphere could further increase stresses in the building envelope when creating a pressurized environment or could make a surface printing process challenging. Precedent case studies aim to counteract these challenges: -The Mars Ice House and the NASA feasibility study The ICE Home. Which uses ice as the main construction material as it is more effective against radiation then regolith-based constructions. Extra measures must be taken to keep the ice from sublimating into the air, e.g. the use of inflatable plastics is proposed. -Foster and Partners autonomous habitation sintering. This process uses regolith as the main construction material, but instead of printing it they fuse the layers together using autonomous swarm robots. -Apis Cor’s X-House is a 3D printed habitat that used Martian concrete reinforced with basalt fibers and expandable polyethylene foam. -AI Space Factory’s MARSHA is a 3D printed habitat that used a biopolymer basalt composite material for 3D printing. Which is effective against stress and to some degree against radiation as the material has a high hydrogen concentration. All these examples are NASA 3D printed habitat challenge contestants and all of them are top surface design proposals. NASA stated that excavation and drilling into any off-Earth location would require large and heavy equipment making it infeasible. However, the team sees an opportunity to investigate possibilities of how autonomous robots could drill into and/or excavate off-Earth and 3D print a subsurface habitat while also considering the restraints of interplanetary space travel. The main idea is to develop a production method, which facilitates excavation, digging and drilling into the surface to produce a subsurface habitats. Subsurface habitation has the advantage of natural protection from the overburden layers of rock and regolith while also being less affected by thermal stresses because the temperature is more stable underground. At the same time through excavation valuable resources are mined for in situ resource utilization (ISRU). Design methodologies are restricted by the method of production and the materials available. The use of locally obtained materials through excavation and the naturally obtained shelter represent the advantage over other design proposals. Autonomous mobile robots will excavate the ground in a sloped downwards spiral movement. The excavated regolith will be mixed with liquid sulfur to create concrete, which is then used by the 3D printing rover to create a structure in the excavated tunnels. As soon as the tunnels are printed, the material in between the tunnels can be removed in order to create a larger cavity that can be used for inhabitation.

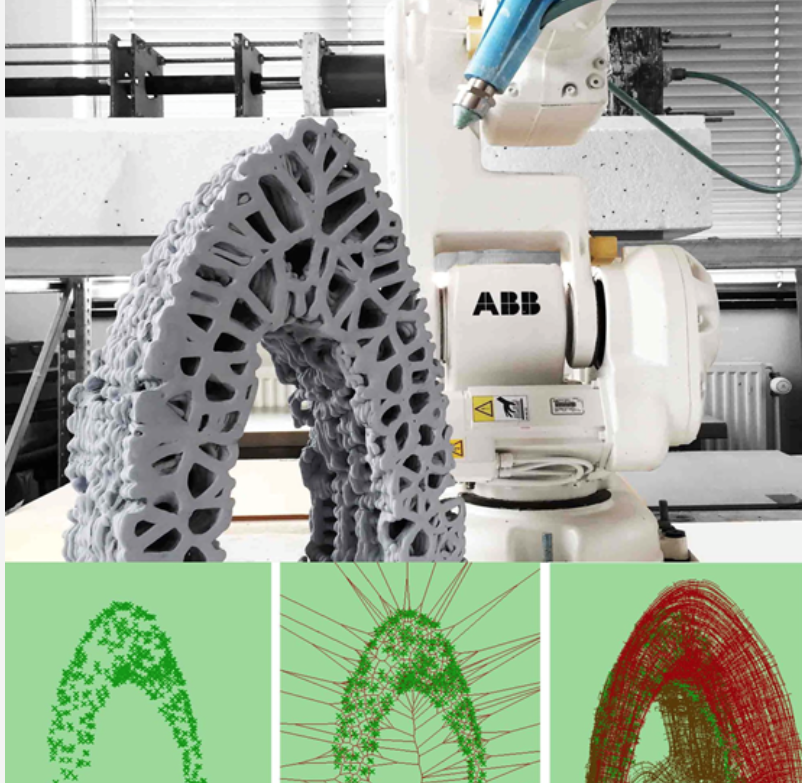

Fig. 2: Additive D2RP using clay

Fig. 2: Additive D2RP using clay

Description

This proposal explores the potential of several technologies developed at TU Delft and ESA for off-earth manufacturing and construction. It builds upon expertise developed in architecture and aerospace engineering.

1. Architecture: Data-driven Design-to-Robotic-Production and -Operation (D2RP&O)

Data-driven D2RP&O integrates advanced computational design with robotic techniques in order to produce performance-driven architectural formations. This implies that design is directly linked to building production and operation (Bier et al. 2018). The overall design of the habitat relies on data-driven simulation of the underground growing inhabitable rhizomatic structure (figure). By analyzing the composition of the terrain suitable locations will be identified in order to excavate and 3D print habitats below ground by means of D2RP&O. The first case study is for a 60-80 m2 habitat that can be extended in time.

Subtractive and additive D2RP will be employed in the following sequence: Subtractive D2RP involving excavation following a regular mining approach is proposed. Excavation is implemented with rovers similar to the ones developed at TU Delft (https://tudelftroboticsinstitute.nl/robots/zebro or https://www.delftsepost.nl/nieuws/algemeen/772027/tu-delft-studenten-bouwen-aan-eerste-nederlandse-maanrover) in a controlled downward spiral movement (figure). D2RP involving milling, drilling, cutting as explored at Robotic Building (RB), TU Delft (http://100ybp.roboticbuilding.eu/index.php/WorkshopHvA) will be employed for the later stages of construction when the interior architecture of the habitats is implemented. Additive D2RP as explored at RB, TU Delft with clay (http://www.roboticbuilding.eu/project/scalable-porosity/) and TPE (http://www.roboticbuilding.eu/project/variable-stiffness/) represents the basis for the 3D printing approach with regolith that is proposed (figure 1c) in this project. The printing system is connected to a rover depositing material following a controlled upwards spiral (figure 1d). By mixing regolith with molten sulfur a mixture is formed that is stronger than concrete. The printed structure is a compression-only i.e. shell structure. It is a structurally optimized porous structure, which has increased insulation properties (fig. 2), requires less material and reduced printing time.

Both additive and subtractive D2RP will be powered by the airborne energy (http://www.roboticbuilding.eu/project/kite-powered-d2rp/) and/or solar cells. In order for the built structures to be inhabitable, environmental control, life support and energy requirements (kite-power system and/or solar panels) for an autarchic habitat need to be considered. Environmental control and life-support system supplies air, water, and food and relies on filtration systems for human waste disposal and air production requiring an average power for a habitat on Mars of 1600 W for a crew of 6 people (Santovincenzo, 2004). Water needs to be stored, used, and reclaimed (from wastewater), although, Mars missions may also utilize water from the atmosphere or ice deposits. Oxygen comes from electrolysis, which uses electricity from solar panels or kite-power to split water into hydrogen gas and oxygen gas. Temperature regulation is achieved using both passive and active systems, which protect from overheating, either by thermal insulation and by heat removal from internal sources (such as the heat emitted by the internal electronic equipment) or protect from cold, by thermal insulation and by heat release from internal sources. Furthermore, shielding against harmful external influences such as radiation and micro-meteorites is necessary. This is achieved by placing the habitat below ground level. In addition, an inflatable structure is proposed to counteract Mars’s low atmospheric pressure which is a threat to human health. The inflatable structure that regulates the indoor pressurized environment is placed in the 3D printed structure. This inflatable structure requires materials such as neoprene,vectran, kevlar or ultra-high-molecular-weight polyethylene by Dutch chemical company DSM (https://www.dsm.com), whom the team would like to involve in the project. The advantage is that the range of required materials can also be reproduced on Mars through in situ resource utilization (ISRU) of silicon, which is proven to be in abundance on Mars. The inflatable structure relies on ESA’s current development for Lunar habitation with Foster and Partners (https://www.fosterandpartners.com/projects/lunar-habitation). Life support systems could include a plant cultivation system, which could also regenerate water and oxygen. Such a system could reuse nutrients via composting waste which is then used to fertilize crops. For instance, research results of the Micro-Ecological Life Support System Alternative (MELiSSA), which is a European Space Agency led initiative, aiming to understand the behavior of artificial ecosystems in order to develop technology for a future regenerative life support system could be integrated in the proposed project. Energy generation by means of solar panels (https://www.tudelft.nl/en/eemcs/the-faculty/departments/electrical-sustainable-energy/photovoltaic-materials-and-devices/) and airborne wind energy are considered.

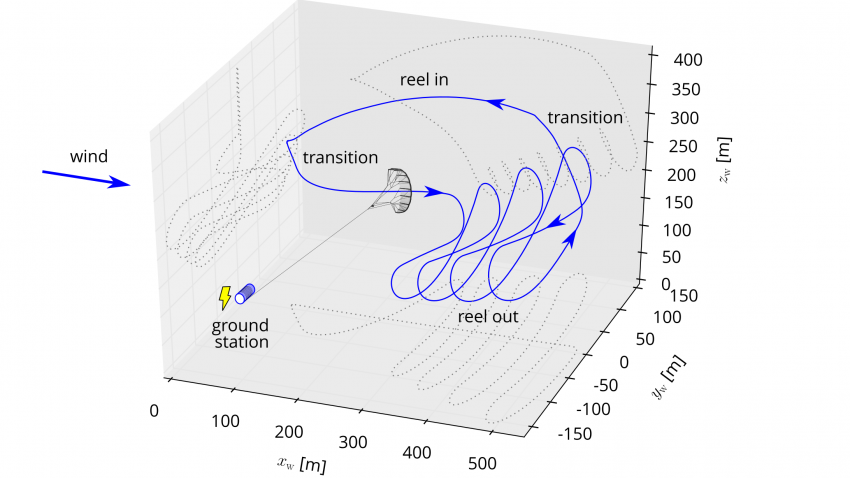

Fig. 3: Airborne wind energy system of TU Delft in operation (top) and simulated energy harvesting cycle (bottom)

Fig. 3: Airborne wind energy system of TU Delft in operation (top) and simulated energy harvesting cycle (bottom)

2. Aerospace

2.1 Airborne wind energy is considered for powering the D2RP&O system as well as the habitat on Mars. Generating energy on Mars with different renewable energy sources, i.e. hybrid wind-solar system has been investigated (Bluck, 2001). The average wind speed on Mars is 10 meters per second (Boumis, 2017), while the density of the Mars atmosphere is about 1% of the density of the Earth's atmosphere. The aerodynamic force that a kite generates depends linearly on the density of the atmosphere, and linearly on the wing surface area. On the other hand, wind speeds are much higher on Mars. Since the power output of a kite power system scales with the cube of the wind speed (Loyd 1980, Schmehl 2013), this means that a speed increase of a factor of two leads to eight-fold power output. As a consequence, the higher wind speeds on Mars counteract, to some degree, the very low density on the red planet (Mersmann, 2015). Another factor that positively influences the flight operation of a kite on Mars is the lower gravitational constant. This means a kite power system can harvest wind energy already at lower wind speeds (denoted as "cut in" wind speed). Researchers at NASA had developed a kite simulator that allows the computational simulation of a kite on Mars, accounting for the above mentioned physical effects (https://www.grc.nasa.gov/WWW/k-12/airplane/kiteprog.html).

In this proposal, the automated kite power system developed at TU Delft will provide the electricity for the D2RP&O system and the habitat. The technology is currently being developed and will need to be adjusted to the operation on Mars (atmosphere with lower density and frequent storms, lower gravity). A flexible wing system with small packing volume and minimal weight is proposed. However, the wing surface area needs to be increased to account for the lower atmospheric density. The present development platform is using an 18 kW generator and produces about 7 kW in good wind conditions which powers about 14 Dutch households. The system would be combined with solar PV to buffer periods of low wind, which would establish a microgrid. The system weighs 150-200 kg when the mass of the motor/generator is used as the driving element. The volume is approx. 2 m3. In effect, the wing surface area will have to be slightly increased to achieve the targeted 7 kW in the Mars atmosphere with substantially lower density. The unique advantage that a fully automated kite power system has over a conventional wind turbine is that its operation can be adjusted to the wind conditions on Mars. When the wind blows stronger, the kite can be depowered and flown in maneuvers that reduce the pulling force, to not overload the system. This is the function of the connected control systems of kite and ground station. Because of the low weight and packing volume and thus a high degree of mobility, the use of kite power systems on Mars has already been considered (Alright, 2019).

2.2 Space systems engineering, autonomous multi-functional robots swarm, and communication equipment: For this project, a swarm of mobile robots i.e. rovers developed by TU Delft (https://tudelftroboticsinstitute.nl/robots/zebro) and/or ESA are considered for implementing tasks such as excavating, transporting and processing i.e. 3D printing. For the development of the space systems, Dr. Angelo Cervone from the Space Systems Engineering chair (who is currently acting as Principal Investigator of the TU Delft contributions to Stardust-R and LUMIO) will bring his expertise in systems engineering, interplanetary small satellite missions and miniaturization of space technology and components. Particularly valuable for the project will be the research previously and currently performed on asteroid exploration, characterization, and exploitation.

Since 2013, TU Delft has been actively working on small-scaled rovers under the name of Zebro Rover. The rovers are especially built for swarming given they are built from the ground up for mass production and have an array of sensors like stereo vision to detect and avoid obstacles and have sensors onboard for localization. These lightweight rovers (2kg to 5kg) are an ideal sensor mobile platforms and can be retrofitted with any instrument like radar and drills to give them a specific use. The 'swarm intelligence' controls the overall behavior of the swarm (>10 rovers) and as it is a decentralized architecture; any number of rovers can be added to the swarm from future missions. To demonstrate the technology in the mobile platform, TUDelft is planned to launch the lunar zebro to the Moon in Q4 of 2022 with future plans of launching more rovers at once to build a lunar-based radio telescope using swarm technology.

Starting in April 2020, the Rhizome project for Off-Earth Manufacturing and Construction will be the topic of a Design Synthesis Exercise at the Faculties of Architecture and Aerospace Engineering. In this exercise, 25 students work for 10 weeks part- and full-time on the challenge of this competition. The set-up models what ESA attempted with their Concurrent Design Facility: https://en.wikipedia.org/wiki/Concurrent_Design_Facility.

Preliminary energy/mass/volume considerations: Total amount of power required is estimated as follows: Printing robot - 425kgs ( robot weight) - 1.53kW - 3.22kgs ( solar cell weight); Life system- 1.6kW - 3.368kgs ( solar cells weight); Labs and communication and miscellaneous- 15.1kW - 31.79kgs (solar cells weight); Drilling rover along with the 25W RTG - weight- 17kgs + 2 lithium ion rechargeable batteries with 150 Wh/kg

PHASE 2.0

Source document: https://docs.google.com/document/d/1DrjV_Pg7G8km8Dxeq0rmxRFBBXfCqPuR/edit?dls=true

PHASE 2.1

Source document: https://docs.google.com/document/d/1t6E8bqWRvZd5bPzjGzk2JaPHGwsOorCk/edit#

References

In-situ resources utilization

Marspedia: http://marspedia.org/In-situ_resource_utilization

Regolith

WIkipedia: https://en.wikipedia.org/wiki/Regolith#Mars and https://de.wikipedia.org/wiki/Regolith

Sulfur (on Mars)

P.L. King, S.M. McLennan: "Sulphur on Mars". Elements (2010) 6 (2): 107–112. https://doi.org/10.2113/gselements.6.2.107 H.B. Franz, P.L. King, F. Gaillard: "Chapter 6 - Sulfur on Mars from the Atmosphere to the Core". In: Volatiles in the Martian Crust, Pages 119-183, 2019. https://doi.org/10.1016/B978-0-12-804191-8.00006-4

"Brewing Sulfur with Martian Water". Astrobiology Magazine. https://www.astrobio.net/mars/brewing-sulfur-with-martian-water/ "NASA Mars Rover Churns Up Questions With Sulfur-Rich Soil". News item 14 March 2007. https://www.nasa.gov/mission_pages/mer/mer-20070314.html Digging on Mars

Digging (on Mars)

"Help NASA Design a Robot to Dig on the Moon". NASA Kennedy Space Center, News item 16 March 2020. https://www.nasa.gov/feature/help-nasa-design-a-robot-to-dig-on-the-moon

"Regolith Advanced Surface Systems Operations Robot (RASSOR) Excavator". NASA Kennedy Space Center, Patent description. https://technology.nasa.gov/patent/KSC-TOPS-7

M. Bartels: "Robot 'Mole' on Mars Begins Digging Into Red Planet This Week". 26 February 2019. https://www.space.com/mars-mole-insight-heat-probe-begins-science.html

"Der Marsmaulwurf und der herausfordernde Boden des Roten Planeten". DLR News Item, 6 November 2019. https://www.dlr.de/content/de/artikel/news/2019/04/20191106_der-marsmaulwurf-und-der-herausfordernde-boden-des-roten-planeten.html

L.S. Gertsch, J. Rostami, R. Gustafson: "Review of Lunar Regolith Properties for Design of Low Power Lunar Excavators Lunar Excavator". International Conference on Case Histories in Geotechnical Engineering 2, 2008. https://scholarsmine.mst.edu/icchge/6icchge/session10/2

Wind energy and other renewables (on Mars)

A. Delgado-Bonal, F.J. Martín-Torres, S. Vázquez-Martín, M.-P. Zorzano: “Solar and wind exergy potentials for Mars”. Energy, Vol. 102, pp. 550-558, 2016. http://doi.org/10.1016/j.energy.2016.02.110

J. Bluck: “Antarctic/Alaska-Like Wind Turbines Could be Used on Mars”. NASA Ames News Item. Oct. 10, 2001 https://www.nasa.gov/centers/ames/news/releases/2001/01_72AR.html

Wind Turbine Power Production Under Current Martian Atmospheric Conditions. Mars Workshop on Amazonian Climate 2018 (LPIContrib.No.2086) https://www.hou.usra.edu/meetings/amazonian2018/pdf/4004.pdf

Marspedia: “Wind turbine”. http://marspedia.org/Wind_turbine Accessed 1 March 2020.

H.W. Haslach, Jr: “Wind Energy: a Resource for a Human Mission to Mars”. Journal of the British Interplanetary Society, Vol. 42, pp. 171-78, 1989. https://www.researchgate.net/publication/252363322_Wind_Energy_a_Resource_for_a_Human_Mission_to_Mars

G. James, G. Chamitoff, D. Barker: “Resource Utilization and Site Selection for a Self-Sufficient Martian Outpost”. NASA/TM-98-206538. April 1998. https://space.nss.org/media/1998-Resource-Utilization-And-Site-Selection-For-A-Self-Sufficient-Martian-Outpost.pdf

(Additional) Phase 1 References

(Additional) Phase 2 References