Msc2G3:Group

TUD 3

Ginevra Nazzarri - Leander Bakker - Erik Bakker

Concept

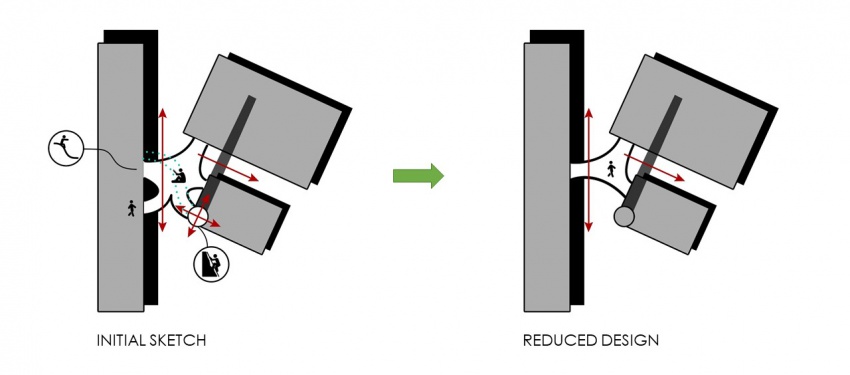

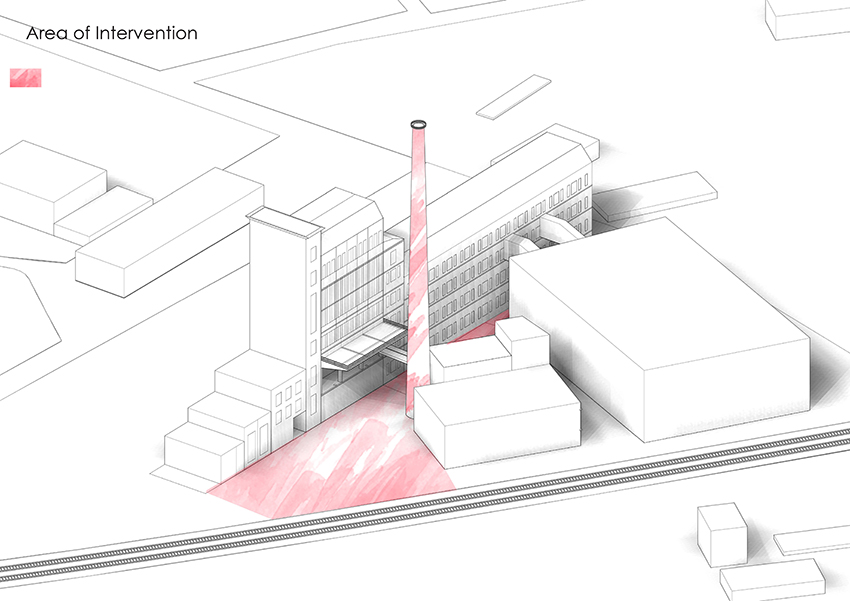

The concept developed by the students of TUD is being defined as a place in between buildings that connects the existing buildings and their people (visitors) in a playful way. The abandoned factory buildings have this ‘negative’ space in between them, which will be the area of intervention for this workshop.

The initial sketch for this 'negative' space was a playground in between these buildings that connects them on multiple levels. Where a visitor can slide, run or climb around or find a place of comfort in the centre. For the sake of the workshop the sketch was reduced to a three-way intersection, leaving out multiple functions. This is something that needs to be addressed in a later stage.

Macro scale

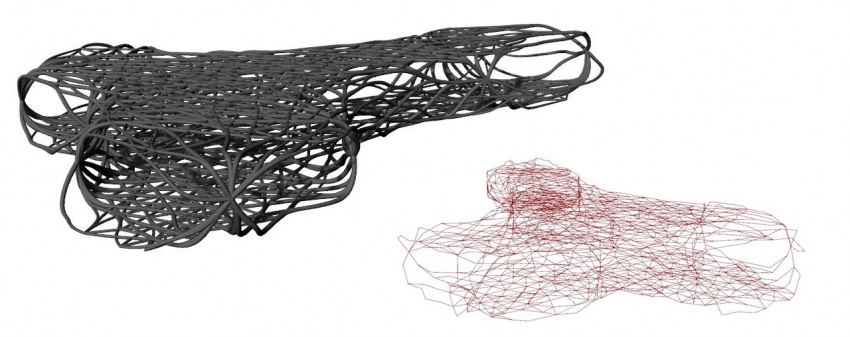

The overall shape was first defined by the reduced sketch from the concept phase. This shape was structurally analysed, resulting in the image below. Here the red areas are pressure points which together create an arch shape in between the existing buildings.

Conclusion

On the macro scale it performs structurally rather well, but performances as functions, view and light have been left out. This is something that needs improvement in a later stage.

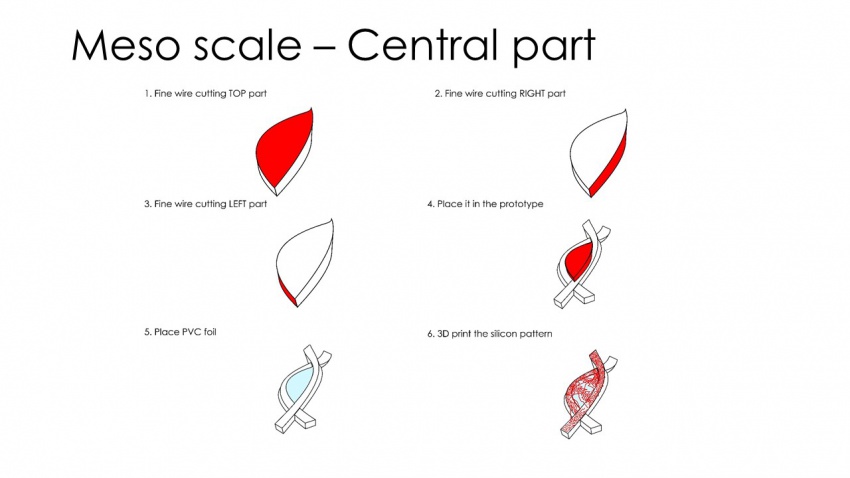

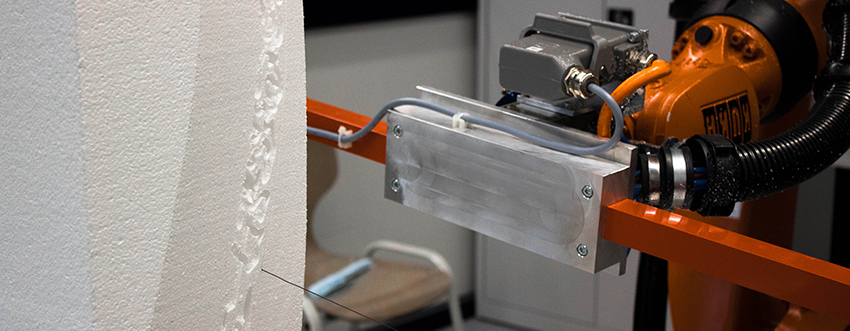

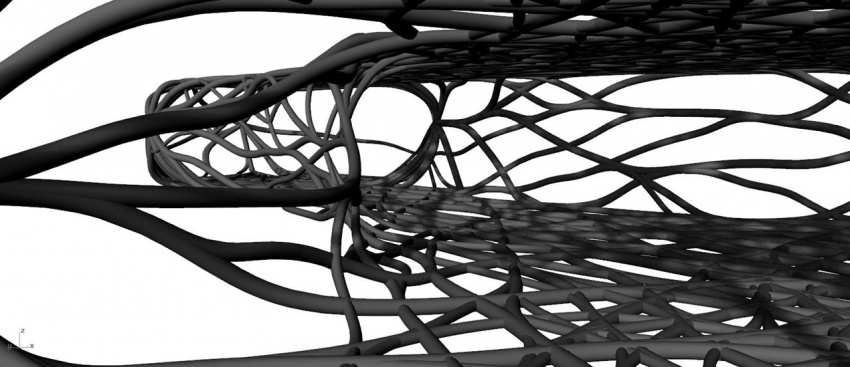

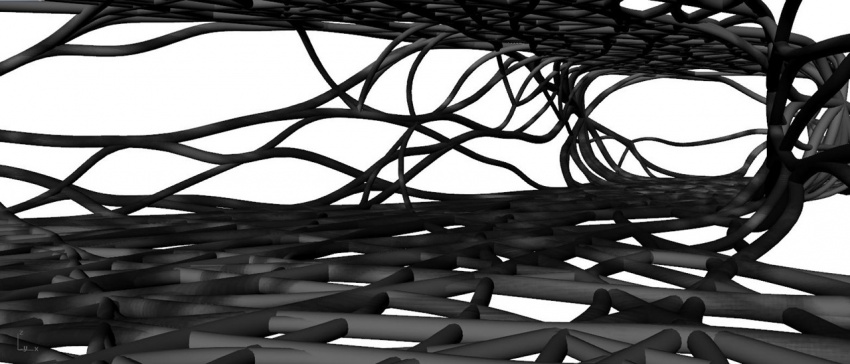

Meso scale

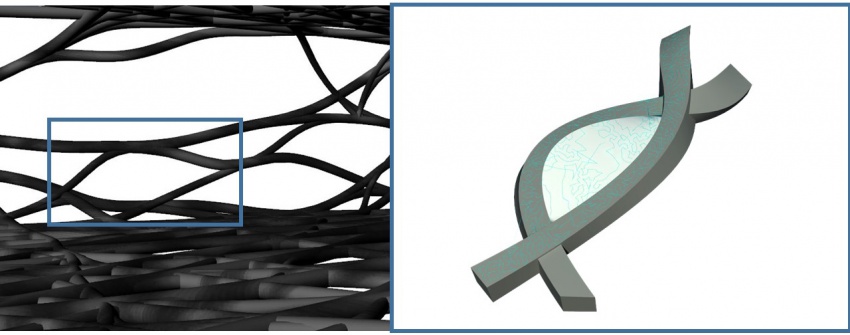

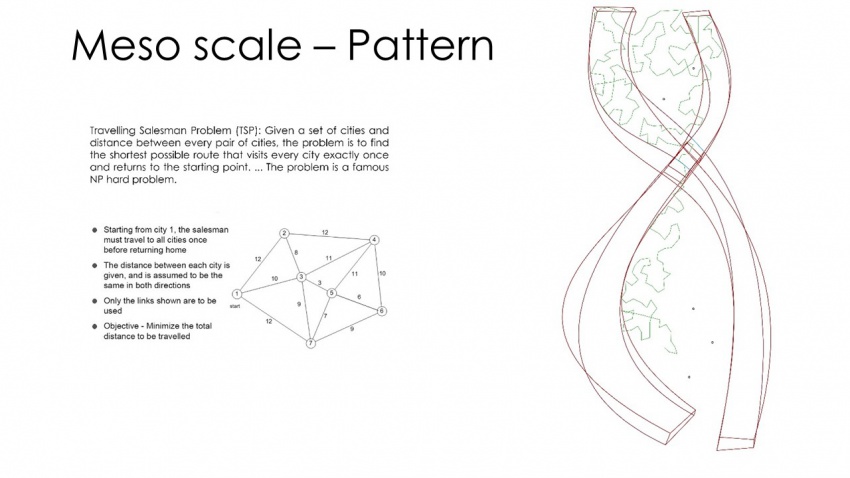

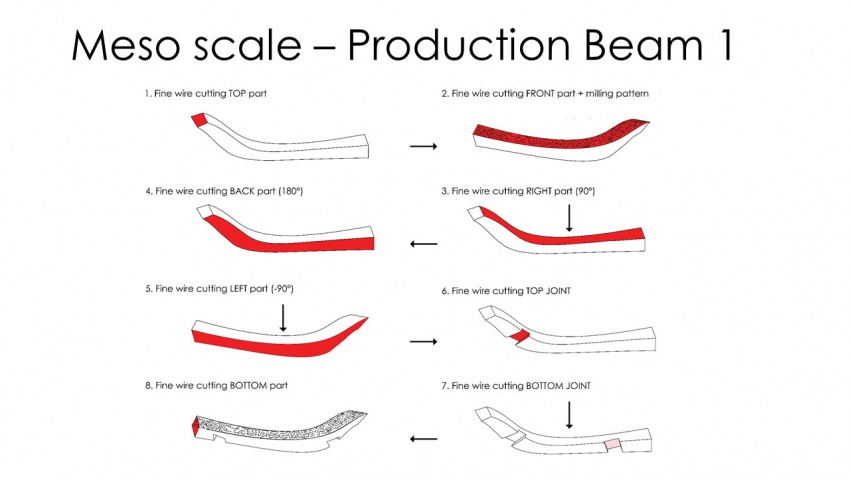

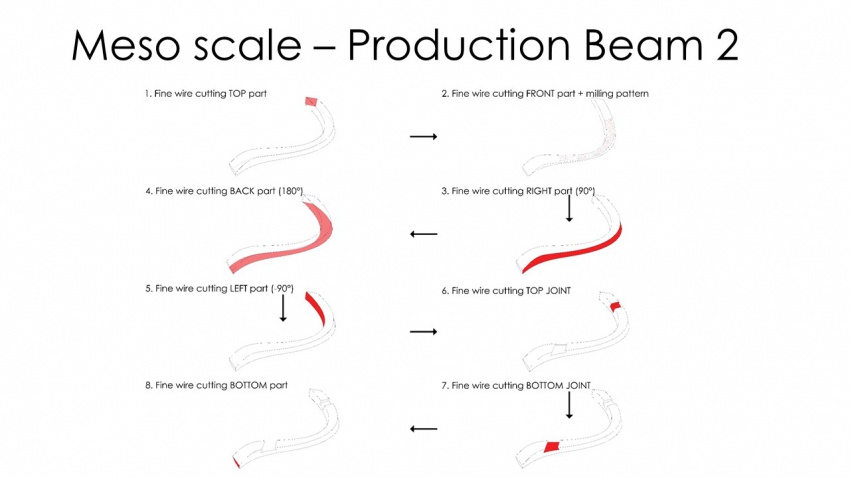

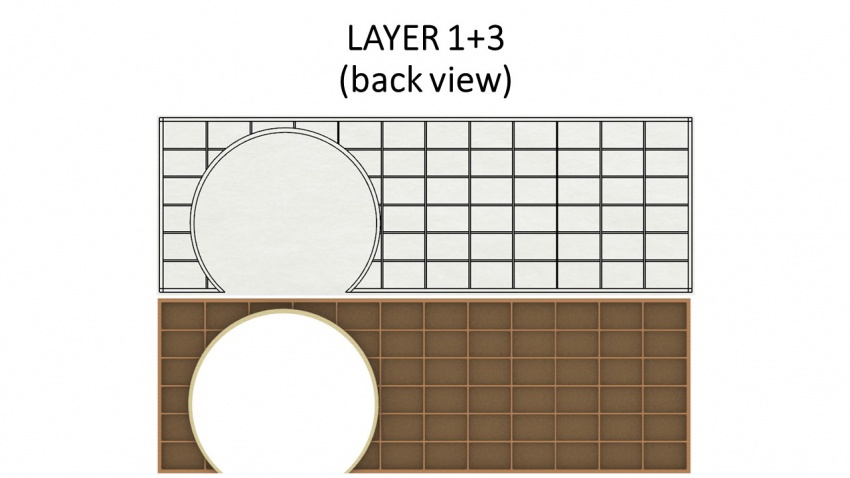

For the meso scale a fragment from the structure was selected to prototype. This selection consists of two curved beams with an 'internal' cushion and pattern on top.