Difference between revisions of "2019W1"

| (6 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

__NOTITLE__ __NOTOC__ | __NOTITLE__ __NOTOC__ | ||

| − | =='''HYBRID COMPONENTIALITY 2. | + | =='''HYBRID COMPONENTIALITY 2.1: D2RP&O'''== |

| − | + | [[File:ws1.jpg | 850px]] | |

<div style="height:30px; width: 850px; margin:0px; padding: 0px; padding-top: 20px; border: 0px;"> | <div style="height:30px; width: 850px; margin:0px; padding: 0px; padding-top: 20px; border: 0px;"> | ||

<div style="float:left; width: 158px; height 30px; border: 1px solid #aaa; margin-right:10px;" align="center"> | <div style="float:left; width: 158px; height 30px; border: 1px solid #aaa; margin-right:10px;" align="center"> | ||

| Line 15: | Line 15: | ||

<div style="float:left; width: 158px; height 30px; border: 1px solid #aaa; margin-right:10px;" align="center"> | <div style="float:left; width: 158px; height 30px; border: 1px solid #aaa; margin-right:10px;" align="center"> | ||

[[2019W1:page3|'''Download''']] | [[2019W1:page3|'''Download''']] | ||

| + | </div> | ||

| + | <div style="float:left; width: 158px; height 30px; border: 1px solid #aaa; margin-right:10px;" align="center"> | ||

| + | [[2019W1:Groups|'''Groups''']] | ||

</div> | </div> | ||

</div> | </div> | ||

<br> | <br> | ||

| + | |||

| + | =='''CONTENT & APPROACH'''== | ||

| + | |||

| + | The 1st workshop introduces students to computational design strategies for Design-to-Robotic-Production (D2RP) and/or Design-to-Robotic-Operation (D2RO) in order to achieve material and process efficiency and/or physical and sensorial reconfiguration. Students are asked to identify aspects related to robotic production and/or operation relevant for their graduation projects and map those onto the proposed exercise. The exercise focuses on hybrid componentiality, which implies that components of various materials and properties are interconnected to establish a whole. | ||

| + | <br><br> | ||

| + | The hybrid components are part of a larger partially paneled structural spaceframe. Two D2RP&O studies are proposed: | ||

| + | 1. D2RP: The development of a 3D printed (metal or reinforced plastic) node for connecting linear (wooden) elements of variable lengths and sizes | ||

| + | 2. D2RO: The development of interactive/responsive panels fitted with sensor-actuators and to be placed on the structural frame. | ||

| + | <br><br> | ||

| + | To be considered are current developments advancing from mechatronics (https://www.youtube.com/watch?v=XdIiS7R5m_4) towards soft robotics (VOCATIV https://www.youtube.com/watch?v=vhomcCEAXCg and AMOLF https://amolf.nl/research-groups/soft-robotic-matter) and from 3D printing (ARUP https://research.arup.com/projects/additive-manufacturing-bringing-3d-printing-to-hard-hat-construction/ and Bartlett https://3dprint.com/tag/bartlett-school-of-architecture/) to self-assembling structures (HYDRA https://www.youtube.com/watch?v=edX-rppn34o and MOLECUBES | ||

| + | https://www.youtube.com/watch?v=2I3xTQXFNAU). | ||

| + | <br><br> | ||

| + | Main questions to be answered are: If static structures harbor dynamic components that can be reconfigured, what are the utopian/dystopian scenarios that are considered, which are the static and the dynamic components, what is the required degree of customisation and how it is to be achieved. Potential customization is explored though functional, environmental, acoustical and structural simulations. | ||

| + | <br> | ||

| + | <br> | ||

| + | ---- | ||

| + | |||

| + | =='''COORDINATORS & TUTORS'''== | ||

| + | |||

| + | Henriette Bier, Arwin Hidding, and Vera Laszlo | ||

| + | <br> | ||

| + | <br> | ||

| + | ---- | ||

| + | |||

| + | =='''STUDENTS'''== | ||

| + | |||

| + | See groups 1,2 and 3. | ||

Latest revision as of 16:08, 3 February 2021

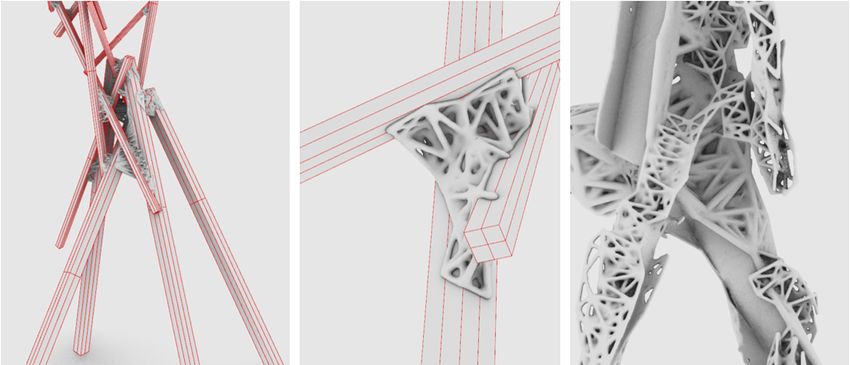

HYBRID COMPONENTIALITY 2.1: D2RP&O

CONTENT & APPROACH

The 1st workshop introduces students to computational design strategies for Design-to-Robotic-Production (D2RP) and/or Design-to-Robotic-Operation (D2RO) in order to achieve material and process efficiency and/or physical and sensorial reconfiguration. Students are asked to identify aspects related to robotic production and/or operation relevant for their graduation projects and map those onto the proposed exercise. The exercise focuses on hybrid componentiality, which implies that components of various materials and properties are interconnected to establish a whole.

The hybrid components are part of a larger partially paneled structural spaceframe. Two D2RP&O studies are proposed:

1. D2RP: The development of a 3D printed (metal or reinforced plastic) node for connecting linear (wooden) elements of variable lengths and sizes

2. D2RO: The development of interactive/responsive panels fitted with sensor-actuators and to be placed on the structural frame.

To be considered are current developments advancing from mechatronics (https://www.youtube.com/watch?v=XdIiS7R5m_4) towards soft robotics (VOCATIV https://www.youtube.com/watch?v=vhomcCEAXCg and AMOLF https://amolf.nl/research-groups/soft-robotic-matter) and from 3D printing (ARUP https://research.arup.com/projects/additive-manufacturing-bringing-3d-printing-to-hard-hat-construction/ and Bartlett https://3dprint.com/tag/bartlett-school-of-architecture/) to self-assembling structures (HYDRA https://www.youtube.com/watch?v=edX-rppn34o and MOLECUBES

https://www.youtube.com/watch?v=2I3xTQXFNAU).

Main questions to be answered are: If static structures harbor dynamic components that can be reconfigured, what are the utopian/dystopian scenarios that are considered, which are the static and the dynamic components, what is the required degree of customisation and how it is to be achieved. Potential customization is explored though functional, environmental, acoustical and structural simulations.

COORDINATORS & TUTORS

Henriette Bier, Arwin Hidding, and Vera Laszlo

STUDENTS

See groups 1,2 and 3.