Difference between revisions of "2020W2"

Max Latour (Talk | contribs) |

Max Latour (Talk | contribs) |

||

| Line 20: | Line 20: | ||

[[2020W2:page4|'''Online''']] | [[2020W2:page4|'''Online''']] | ||

</div> | </div> | ||

| − | <div style="float:left; width: 158px; height 30px; border: 1px solid #aaa; margin-right:10px;" align="center"> | + | <div style="float:left; width: 158px; height 30px; border: 1px solid #aaa; margin-right:10px; margin-top:10px;" align="center"> |

[[2020W2:page5|'''Prototyping''']] | [[2020W2:page5|'''Prototyping''']] | ||

</div> | </div> | ||

Revision as of 21:41, 6 November 2020

Componential Hybridity

CONTENT & APPROACH

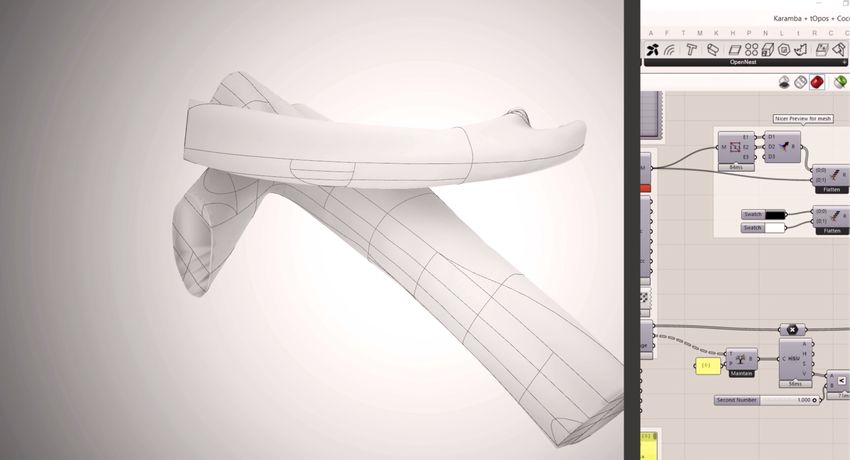

The workshop introduces students to computational design strategies for Design-to-Robotic-Production and -Operation (D2RP&O) in order to achieve material and process efficiency as well as physical and/or sensorial reconfiguration. Students are asked to identify aspects related to robotic production and operation that are relevant for the CS project. The exercise focuses on hybrid componentiality consisting of elements made of circular wood and connected with 3D printed steel nodes.

The following D2RP studies are proposed:

1. Subtractive D2RP: The development of a structurally optimized curvy-/linear component milled from circular wood,

2. Additive D2RP: The development of a structurally optimized 3D printed node.

DELIVERABLES

a. 1 to max. 2 minutes video of D2RP process,

b. Report (1500 words) consisting of textual and photo/graphical documentation of physical prototypes and design to fabrication process developed during the semester,

c. Clean Rhino and Grasshopper files and refined version D2RP procedures,

d. 3D printed model, 1:1 prototypes, and tests.

COORDINATORS & TUTORS

Henriette Bier, Max Latour, and Vera Laszlo (TUD) | Marta Malé-Alemany, Tony Schoen, and Marco Galli (HvA)

STUDENTS

Group 1 (TUD) and Group 2 (HvA)